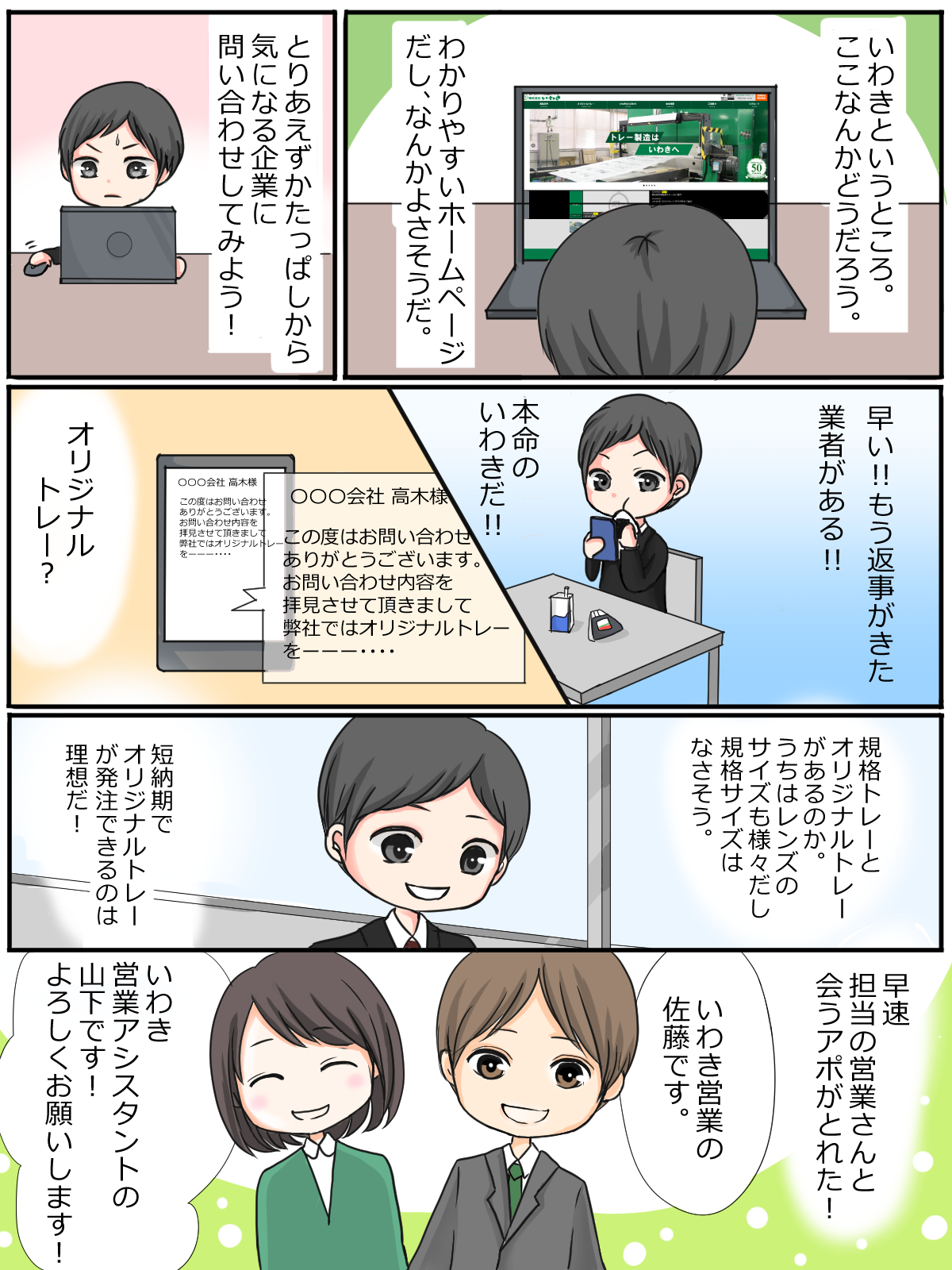

お客さまの夢と希望を製品に。「いわき」のオリジナルトレー

長年にわたる実績を糧に、最新設備によるコスト削減、精度の向上を目指し、スピード納品と低価格を実現

お客様の「あったらいいな」を叶えるオリジナルトレーは製品に合わせた世界に一つだけの完全オーダーメイドです。

企画設計(図面作成)から金型製作・試作・量産成形に至るまで、大きさ、材質、形状問わず、お客様の必要なトレーを最新設備と創業以来培ってきたノウハウで形にします。

工業系トレーならどんなものでも対応可能です。

真空成型、真空圧空成形、射出成型等、多様な成形方法から最も適した成型方法を御提案させて頂きます。

まずは、ご相談からで構いませんのでお気軽にお問い合わせください。

各用途の紹介(一例)

(1)光学部品、レンズ、基板 (2)IC用 (3)水晶部品用 (4)電子部品用 (5)精密機器用 (6)自動車部品用 (7)車載部品用 (8)自動機対応工程間パレット (9)ダネッジ (10)医療用トレー

搬送・保管・保護を目的とすることが多いです。

その他、上記にないものもお気軽にご相談いただければ幸いです。

取扱実績材料(一例)

[真空]

・PET ・PS ・PP ・PC ・カイダック ・汎用樹脂 ・複合樹脂 ・エンジニアプラスチック

[射出]

・ABS ・PP ・PS ・PC ・PBT ・変性PPE ・その他汎用樹脂~スーパーエンプラ

その他、上記にないものもお気軽にご相談いただければ幸いです。

クリーントレーに関して

要求されるクリーン環境に対応した精密洗浄を行い、クリーンパックにて出荷致します。

半導体・光学・電子・精密機器及び、医療機器など、防塵、静電気、脱ガス対策をクリアした材料及び設計にてご提案させていただきます。

漫画でご紹介。工業用トレーをオリジナルで作る!